Ball Plungers for Indexing, Locating, and Spring-Loaded Positioning in Mechanical Assemblies

When your mechanical design demands precise positioning, repeatable alignment, or detent locking, Ball Plungers provide an elegant and space-saving solution. These small components deliver spring-loaded force via a smooth ball tip, making them ideal for light-duty indexing, guiding, or retaining mechanisms.

At Dongguan Sango Hardware Fasteners Co., Ltd., we manufacture a wide range of ball plungers that deliver consistent force, long cycle life, and reliable performance in fixtures, sliding elements, hinged systems, and adjustable panels.

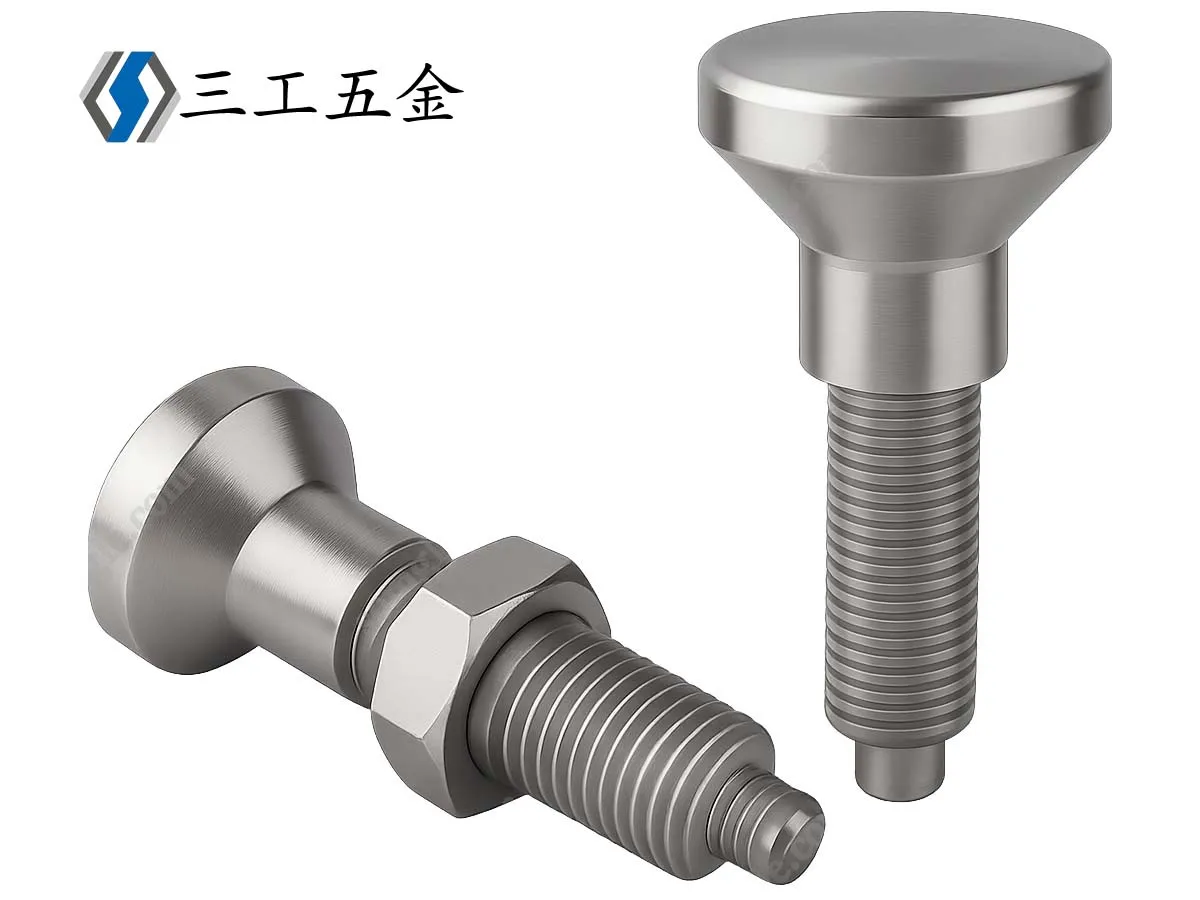

1. What Is a Ball Plunger?

A Ball Plunger is a spring-loaded device consisting of a small steel or plastic ball housed in a threaded or press-fit body. When the ball is pushed in, the internal spring compresses, and when released, the spring force pushes the ball out to engage with a detent, groove, or mating surface, providing tactile feedback and position control.

🔩 Key Benefits:

- Provides light retention, indexing, or alignment

- Allows easy sliding or rotation with detent feel

- Compact and easy to install into threaded or press-fit holes

- Available in various materials, forces, and mounting styles

- Long life cycle with smooth engagement

2. Common Types of Ball Plungers

🔹 Threaded Ball Plunger

- Screws directly into a tapped hole

- Used in adjustable stops, sliding tracks, and rotary knobs

🔹 Press-Fit Ball Plunger

- Inserted into a smooth bore without threads

- Ideal for space-constrained or high-volume assemblies

🔹 Hex Socket Ball Plunger

- Features a hex drive for precise torque installation

- Suitable for fixture bases, robotic positioning, and precision jigs

🔹 Slotted Ball Plunger

- Slotted drive head allows adjustment with a flathead screwdriver

- Used in control knobs, adjustable cams, and lab equipment

🔹 Plastic Ball Plunger

- Features a nylon or POM ball for non-marring contact

- Ideal for delicate surfaces, electronics, or optics mounts

3. Applications of Ball Plungers

Ball plungers are commonly used in assemblies requiring light holding force, adjustable indexing, or smooth positioning:

- 🧰 Mechanical jigs and fixtures for workpiece retention

- ⚙️ Sliding panels and access doors for detent locking

- 🧪 Test instrumentation and optical benches

- 🛠 Automation systems with spring-loaded mechanical stops

- 📦 Packaging machines with adjustable components

- 🔬 Microscope and camera mounts for click-stop positioning

4. Material and Finish Options

| Component | Material Options | Notes |

|---|---|---|

| Body | Stainless Steel, Carbon Steel, Brass | Stainless for corrosion; brass for soft installs |

| Ball | Hardened Steel, Stainless, Plastic (POM, Nylon) | Nylon ball for delicate surfaces |

| Spring | Stainless Steel or Music Wire | Music wire for higher preload; SS for corrosion resistance |

Finish options:

- Black oxide for carbon steel plungers

- Passivation for stainless steel plungers

- Zinc plating for improved corrosion resistance

- Nickel plating for smoother operation and appearance

- Plastic coating for noise reduction or aesthetics

5. Customization from Sango Hardware

We offer:

- 📏 Thread sizes: M2–M16 or #2–5/8"

- ⚙️ Spring forces: Light (0.5N) to heavy (30N) preload

- 🧩 Ball diameters: 1mm to 8mm

- 🧰 Body styles: Threaded, press-fit, shoulder, flange, hex-head

- 🔧 Material choices: SS303/SS316, carbon steel, brass, nylon, POM

Also supported:

- CAD drawings and force-displacement charts

- Laser marking for part traceability

- OEM/ODM customization and packaging

6. Case Study: Ball Plungers in Adjustable Sliding Gates

Client: Factory automation integrator

Problem: Manual gates in conveyor stations lacked consistent stop points, causing alignment errors

Sango Solution:

- Supplied M6 threaded ball plungers with medium preload and nylon tips to prevent wear

- Delivered pre-assembled with thread-locker for drop-in installation

Result:

- Improved repeatability and click-stop feel

- Reduced component wear and adjustment time

- Client standardized Sango ball plungers across all future designs

7. Why Choose Sango Hardware for Ball Plungers?

🏭 Micron-Level Precision

- CNC-turned bodies, precision springs, and hardened ball seating

🧪 Full Performance Testing

- Spring load testing, friction cycles, salt spray resistance

📐 Engineering Support

- Selection by force/load curve, custom fits, mating surface consultation

📦 Certified Global Supply

- ISO 9001, RoHS, REACH approved with global logistics and OEM packaging

8. Conclusion: Compact and Reliable Positioning with Ball Plungers

Whether you need to index components, guide sliding parts, or secure light loads, Ball Plungers offer a compact and effective solution. With custom preload options, multiple material choices, and long life cycles, Sango Hardware provides ball plungers tailored for your precision mechanical needs.

Contact Dongguan Sango Hardware Fasteners Co., Ltd. today to get expert support on ball plunger solutions for your application.