Quick Lock Pins for Rapid Changeover in Fixtures and Machine Assemblies

In industrial settings where efficiency equals profitability, every second counts. That’s why engineers and operators increasingly rely on Quick Lock Pins—simple yet powerful components that enable tool-free, rapid locking and unlocking of machine parts, fixtures, and modules.

This article from Dongguan Sango Hardware Fasteners Co., Ltd., a leading fastener manufacturer with 20+ years of experience, explores the design, application, and customization of Quick Lock Pins.

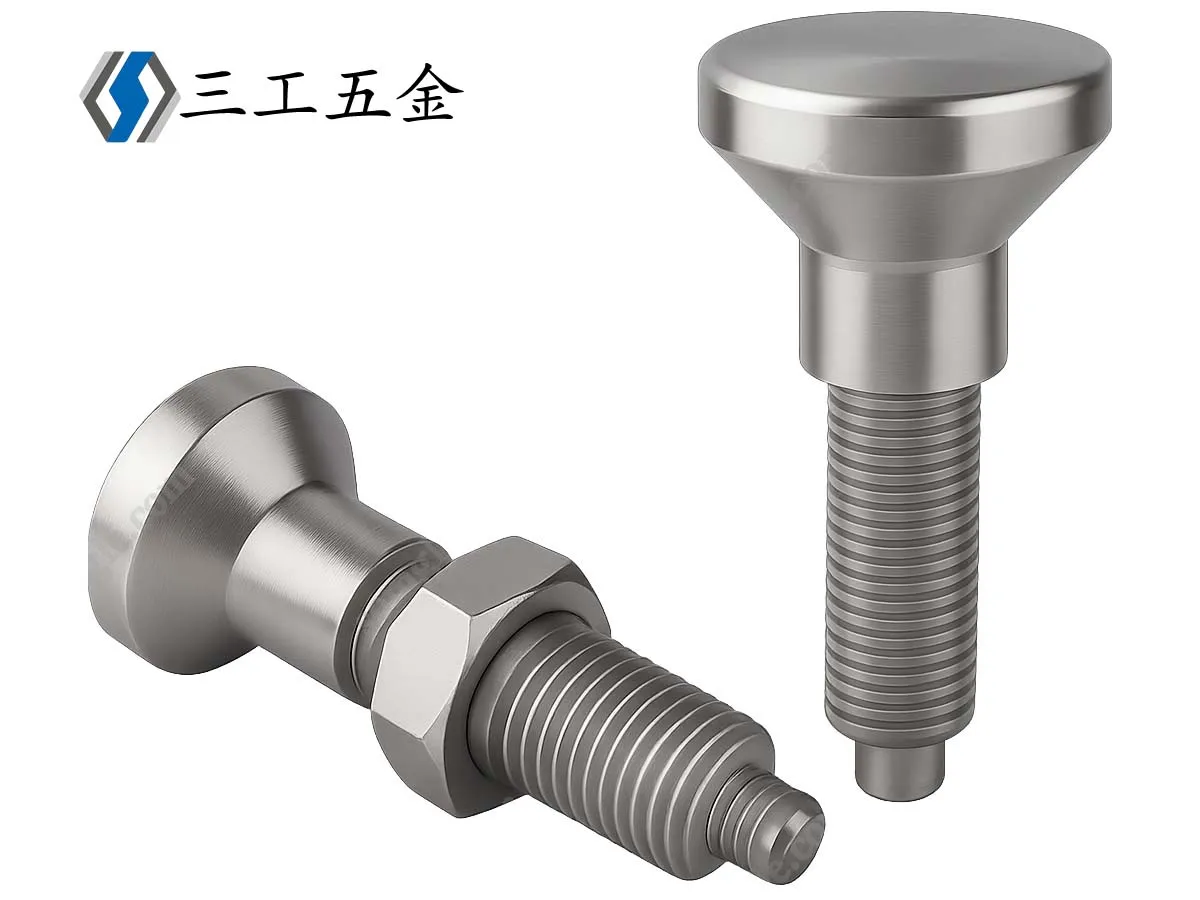

1. What Is a Quick Lock Pin?

A Quick Lock Pin is a spring-loaded mechanical pin designed for fast engagement and release without the need for tools. Typically used in modular fixtures, machine setups, or adjustable structures, quick lock pins enable secure fastening and rapid repositioning.

🔩 Key Benefits:

- Instant locking/unlocking

- Repeatable and secure positioning

- No tools required

- Suitable for high-frequency adjustments

- Strong shear and tensile resistance

2. Common Types of Quick Lock Pins

🔹 Push-Button Locking Pin

- Internal spring retracts ball bearings upon button press

- Ball bearings expand to lock in place

- Ideal for jigs, fixtures, and changeable mounts

🔹 Detent Lock Pin

- Uses spring-loaded ball at the tip

- Locks into place with friction

- Common in lighter-duty positioning tasks

🔹 Ring Pull Lock Pin

- Pull ring releases the locking mechanism

- Used in compact spaces where buttons aren’t accessible

🔹 T-Handle Lock Pin

- Ergonomic grip for heavy-duty applications

- Offers better leverage and torque

🔹 Heavy-Duty Quick Lock Pin

- Larger shaft, hardened steel, dual locking mechanism

- Suitable for robotic arms, lifting jigs, and vehicle assembly stations

3. Where Are Quick Lock Pins Used?

Quick lock pins are used across industries that prioritize modularity, safety, and speed:

- 🛠 Modular fixture systems

- ⚙️ Automation and CNC workholding

- 🏋️ Fitness equipment and resistance settings

- 🧰 Transport crates and foldable structures

- 🚀 Aerospace ground support tooling

- 📦 Packaging and sorting machinery

4. Choosing the Right Quick Lock Pin

| Application Need | Recommended Pin Type | Suggested Material |

|---|---|---|

| Lightweight structure | Detent pin | Aluminum or carbon steel |

| High-load clamping | Push-button or dual-ball pin | Hardened steel |

| Corrosive/outdoor environment | Stainless steel quick lock pin | SUS304/SUS316 |

| Ergonomic or gloved operation | T-handle or ring pull pin | Stainless + plastic grip |

| Limited access space | Low-profile head or ring type | Carbon steel, black oxide |

5. Custom Manufacturing Options from Sango Hardware

We support:

- 🔩 Diameter range: Ø3mm to Ø20mm

- 🔧 Shaft length: 10mm to 150mm

- 🧷 Head styles: Button, ring, T-handle, L-handle, knurled

- ⚙️ Materials: Carbon steel, stainless steel, aluminum alloy

- 🛡 Finishes: Black oxide, zinc-plated, anodized, electropolished

- 🛠 Accessories: Lanyards, locking rings, washers

We also offer laser-engraved branding, color-coded buttons, and assembly guides.

6. Case Study: Reducing Downtime with Quick Lock Pins

Client: Southeast Asia automation integrator

Problem: Traditional screw bolts caused 15-minute downtime during fixture changeovers

Sango Solution:

- Delivered M10 stainless steel push-button quick lock pins with retention lanyards

- Ball lock rated for 1200N shear load

- Installed into quick-exchange pneumatic fixture base

Result:

- Fixture change time reduced to under 1 minute

- Operator error eliminated

- Maintenance frequency decreased

7. Why Choose Sango Hardware for Quick Lock Pins?

🛠 End-to-End In-House Manufacturing

We use CNC turning, broaching, and precision grinding for exact fits and finishes.

📐 Custom Prototyping in 7 Days

You provide the specs or model—we deliver ready-to-test parts fast.

🧪 Full Inspection & Testing

Spring force, locking tension, ball retention, salt spray—all measured and documented.

📦 Global Export Support

RoHS, REACH, ISO 9001, English packaging, private labels, and technical drawings included.

8. Conclusion: Fasten Smarter, Not Harder

Whether you're upgrading fixtures, improving machine uptime, or simplifying user adjustments, Quick Lock Pins offer a durable, user-friendly solution.

Contact Dongguan Sango Hardware Fasteners Co., Ltd. today for high-performance locking pins—customized for speed, safety, and precision.